Quality System

Quality & Inspection

Quality and Accurate inspection is the utmost requirement of the customer and We at Arihant Moulds and Dies to ensure that we deliver the as per our customer requirement. Our Tag line ” Passion for precision ” is the reflection of the same.

We use the best in class measuring and testing equipment’s from Mitutoyo. We can inspect all kind of components with the instruments which are capable to measure up to 1 micron.

Our quality engineers are well trained to operate all these sophisticated instruments and thus help us to ensure the right quality product development and supply.

Quality Capabilities

Our Quality Management system comprises of 1st stage Inspection, Process Monitoring, last stage inspection by use of GOM 3D Scanning Services & Die Spotting.

Further the mould is tried out in its In-house facility which further correlates the dimensions and casting internal quality as well.

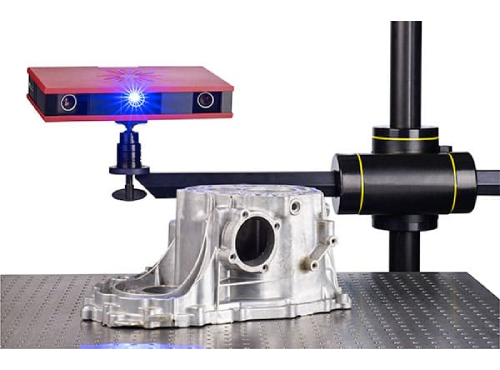

GOM 3D Scanner

Camera

- Resolution: 8 or 12 megapixels

- Connection: Gigabit Ethernet

- Scanning speed: approx. 1 second

ATOS System is the market leader and largest selling Blue light scanning system in the world.It is being regularly used by automotive companies around the world for a wide range of applications including 3D-Scanning, Reverse Engineering Services, and Inspection.

Spotting Press

Spotting is one of the quality assurance tasks in mold and die making. It helps to deliver the best possible products that have a very long service life and themselves ensure faultless products in everyday production. Even for giant dies, fractions of millimeters determine whether a die seals when closing.

SXKH DIE SPOTTING

- Working table size : 1800 x 1500mm

- Max. Daylight : 1870mm

- Min. Daylight : 170mm

- Tonnage handle: 300 T Min to 1400 T Max