- Home

- Investment Mould Makers in Chennai

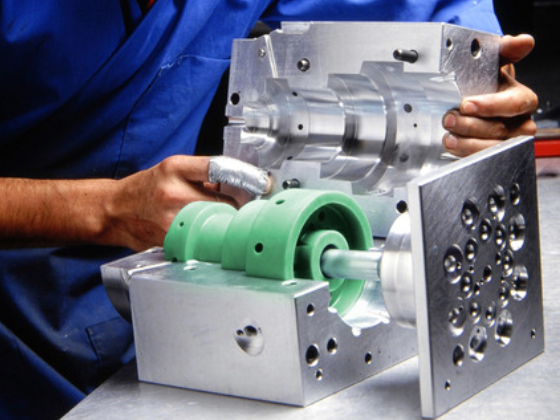

The investment casting process consists of several steps: metal die construction, wax pattern production, ceramic mold creation, pouring, solidification, shakeout, and cleanup.

The wax pattern and ceramic mold are destroyed during the investment moulding casting process, so each casting requires a new wax pattern.

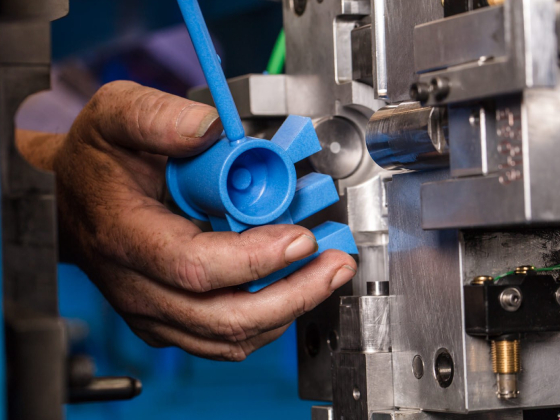

A gating system (sprue, runner bars, and risers) is attached to the wax mold. For smaller castings, several wax patterns are attached to a central wax gating system to form a tree-like assembly. A pouring cup, typically attached to the end of the runner bars, serves to introduce molten metal into the mold.